Lithium Grid News: Evaluating the dimensions of the battery is really a lot of sub-projects.2) What is the battery system? According to this requirement, battery life can be divided into cycle life.

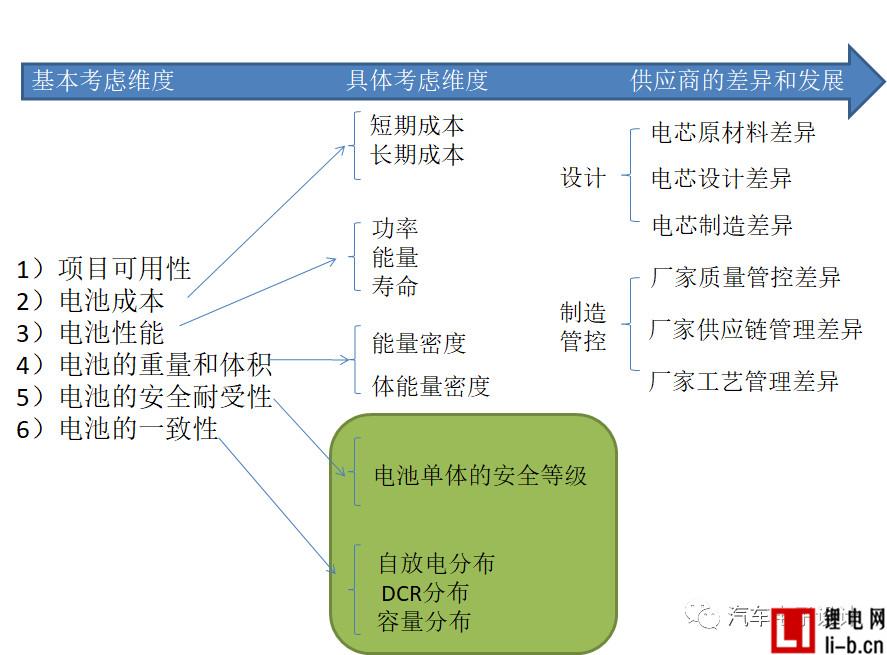

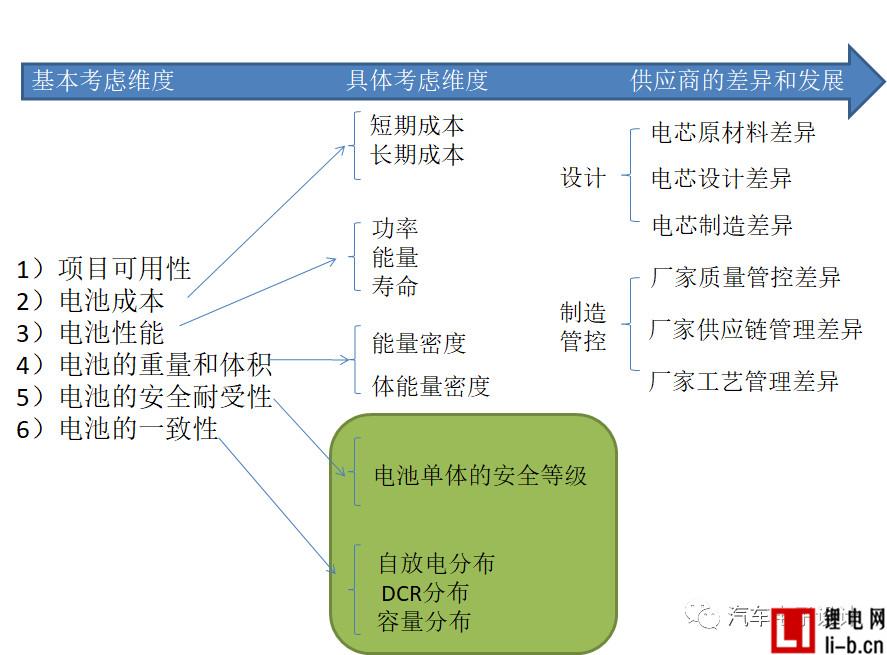

Lithium Grid News: Evaluating the dimensions of the battery is really a lot of sub-projects. The comprehensive evaluation of a supply relationship is really quite a lot. We can only sort out some clues from a partial and overall weighting factor.

Because the overall competitive car is the first, 2018-2019 is the timing of supply and supply than the supplier, and the long-term competitiveness is something we need to observe and test. First meet these basic requirements and then consider other.

Summary of previous notes:

Nowadays, the car is also a battery. How to evaluate the battery inside a car is reliable, safe and durable. This is a big problem. This article is trying to talk about this here, let's talk about how to evaluate a battery. In this respect we can at least be divided into two levels:

1) How about the battery unit?

2) What is the battery system?

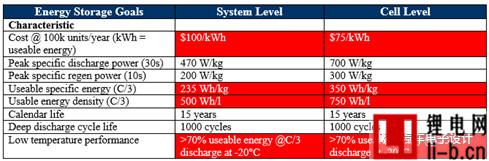

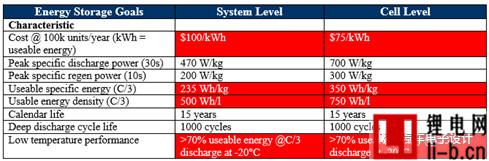

Table 1 Battery needs to be viewed from the monomer and system level

To simplify, a battery system works in the whole vehicle, and it also involves the matching and coordination between the team responsible for the battery system and the vehicle development. However, based on the above main objectives, we evaluate the main indicators of a battery system. The above parameters are expanded.

Figure 1 Relationship between battery and vehicle

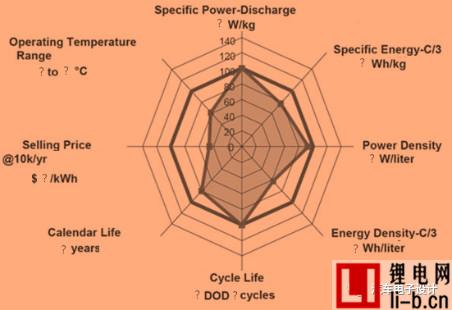

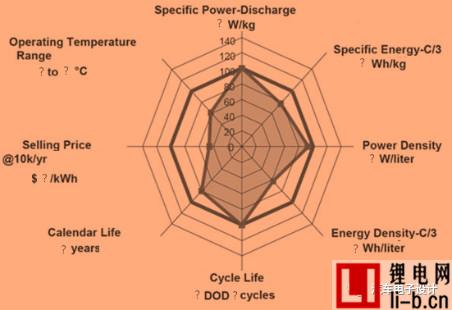

In the process of screening the battery, it is necessary to comprehensively draw each parameter into a spider map, and then select the battery according to the actual situation to match the needs of the whole vehicle. It is important to note that in the three different branches of hybrid , plug-in hybrid and pure electric vehicles , the battery's characteristic requirements are more differentiated. In a class of batteries, such as pure electric vehicles, compared with different car companies and battery manufacturers, the requirements of the indicators are more intuitive and demand convergence.

Figure 2 Spider map to assess the basic performance of the battery

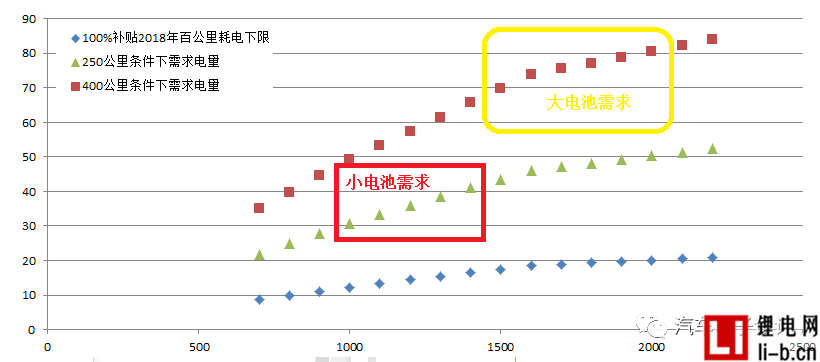

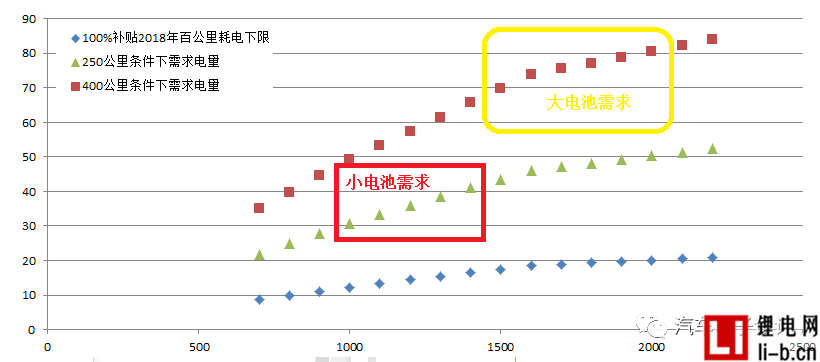

1) High energy density / high power density

The energy density of a battery refers to the energy contained per unit weight or unit volume; the power density refers to the value of the maximum discharge power per unit weight or volume. The energy density per unit weight of the battery has now become the most important indicator of the advancement of battery technology and the direct link to subsidies. It can also be understood that within the limited space and total weight of the vehicle, only by actually reducing the volume and weight of the battery pack can the full use of its transport characteristics, the most powerful electric vehicle is riddled with a turtle shell running.

There is a certain contradiction between the energy density of the battery and the safety of the battery. As the energy density increases, the safety and safety redundancy boundary of the battery are limited. At this time, for the vehicle, more needs to be done. work.

2) Battery life

Lifetime is one of the most critical indicators for power battery applications in automobiles. This is mainly due to the consideration of the vehicle owner's useful life and mileage. According to this requirement, battery life can be divided into cycle life. And the calendar life is measured in two.

Cycle life refers to the internal attenuation of the battery after the number of charge and discharge cycles of the battery through a certain depth of discharge.

Calendar life is the decay of the battery itself over time.

These two parameters are also the most important assessment basis in the power battery roadmap.

Figure 3 Power Battery Roadmap

3) Operating temperature range: including low temperature performance and high temperature performance, we generally characterize the operating temperature of the battery, and this operating temperature is directly related to the power output of the battery. We generally become a map of power.

Low-temperature performance: Under the low temperature, the lithium ion and electrode materials inside the battery maintain high activity, the remaining capacity is high, the discharge capacity is reduced, and the charging rate is allowed to be large. A drop in temperature will cause the remaining capacity of the lithium battery to decay into an acceleration situation. The lower the temperature, the faster the capacity decays. At low temperatures, the activity of lithium ions and electrode active materials decreases, and the rate at which lithium ions are embedded inside the negative electrode material is seriously degraded. When charging beyond the allowable power of the battery, a large amount of lithium ions accumulate around the negative electrode, and lithium ions embedded in the electrode are directly deposited on the surface of the electrode to form an elemental crystal of lithium.

High temperature performance: It means that the battery positive and negative materials, diaphragm and electrolyte can maintain good stability at higher temperature, can work normally at high temperature, life will not accelerate decay, high temperature is not easy to cause thermal runaway accident. Generally, the maximum operating temperature of a lithium battery is around 50 °C. The SEI film on the surface of the negative electrode can start to dissolve at about 90 °C, so that the cell enters the self-heating stage, and the extra temperature rises from the tropics. This is the main reason for the power limitation that we need to introduce into the battery management system.

Next, let's talk about the battery system. In the battery system, you need to meet more regulations and internal requirements. The main requirements for the certification and unified comparison requirements for unified China are as follows.

The industry standard QC/T 743 includes electrical performance and safety performance test items. The national standard is divided into two groups of standards. The first component is GB/T 31484 (cycle life), GB/T 31485 (safety performance) and GB/. T 31486 (electrical performance); Group 2 is GB/T 31467.1 (high power application electrical performance), GB/T 31467.2 (high energy application electrical performance) and GB/T 31467.3 (safety performance).

GB/T 31484, GB/T 31485, GB/T 31486 evolved from the QC/T 743 standard, re-divided the relevant content of the QC/T 743 standard, and upgraded on this basis, and developed a more electric Three independent standard specifications for actual vehicle use.

The GB/T 31467 series of standards is non-equivalent to the ISO12405 series of standards.

In the next step, the above content will further restrict the safety in the form of mandatory standards, "Electric Vehicle Safety Requirements" and "Safety Requirements for Lithium Ion Power Battery for Electric Vehicles".

This is equivalent to a unified quantification of battery safety and a basic bottom line.

Summary: I feel that I need to see the normality and transients of many things. I need to grasp the long-term principles and short-term compromises.

Online map

Online map Collection Website

Collection Website