811 will start to increase its volume. The parameter control of the specific doping coating and the process control of the production line are much more difficult.

Lithium Network News: According to the State Ministry of Industry, "the auto industry long-term development plan," which called 2020 battery single energy density reached 300Wh / kg, which is one of the industry's research efforts target.

From the current technology point of view, high nickel ternary positive electrode + silicon carbon negative electrode is the most feasible commercialization scheme, and the positive nickel nickelization trend is very clear. There is uncertainty after 2025, and the commercialization of lithium-rich manganese-based and solid-state batteries needs to be tracked . Therefore, the life cycle of high-nickel ternary anode products is expected to be at least 5-10 years. At present, cylindrical power batteries have taken the lead in achieving high-volume production of high-nickel products. The breakthrough of square and soft-package batteries is coming soon. In 2019, the industry will usher in a universal breakthrough in mass production of high-nickel products.

By 2020, the NCM811 anode market will exceed 20 billion. Don't you know?

Core logic:

1. The high-nickel power battery scale production turning point has arrived, and high nickel is a medium-cycle industry trend.

2. In 2018, the 811 positive electrode began to increase its volume, and the market will break 20 billion in 20 years.

3. The threshold of high-nickel cathode technology will be greatly improved, which will reshape the industrial structure.

4. The amount of cobalt used in the high-nickel positive electrode is reduced, the cost is significantly reduced, and the profitability is enhanced.

The advantages of high-nickel power batteries are significant, which can significantly increase the unit cost of energy density reduction.

The energy density is significantly improved, the light weight reduces the power consumption of 100 kilometers, and the mileage of passenger cars is improved. At present, the energy density of 811 power battery products may be increased by 15-20% compared with 523 products, and the further performance optimization of subsequent high-nickel cathode products can be increased to more than 30%. The increased energy density means that batteries of the same weight can provide more power, lighter and lighter, reduce power consumption by 100 kilometers, and significantly increase cruising range, which is essential for passenger cars with limited space and sensitivity to endurance performance.

At the same yield, an increase in energy density will significantly reduce the unit cost of the power battery. Cell energy density = positive gram capacity x voltage x positive mass ratio, 811 positive gram capacity is higher, can increase the cell capacity under the same amount of other materials, meaning that the cost per other wh material is reduced, in the same In the case of yield, the cost per wh of the battery will decrease in the same proportion. The current 811 gram capacity is used for calculation. Regardless of the pass rate, the cost per wh can be reduced by about 14%.

Since the 811 power battery product is in the early stage of industrialization, the production environment is demanding and the process control is difficult, resulting in a lower pass rate and higher production cost. However, with the accumulation of mass production experience, the technical strength of the positive electrode and battery manufacturers has gradually increased. It is expected that the yield rate will gradually increase, and the cost advantage of high nickel power batteries will gradually emerge.

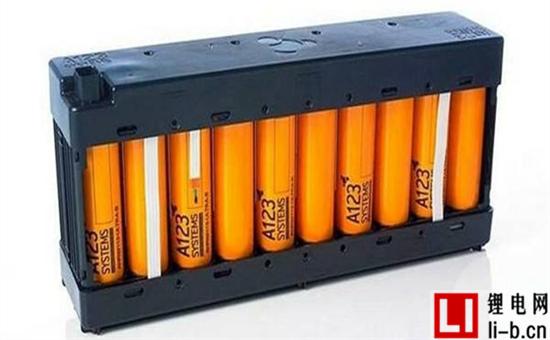

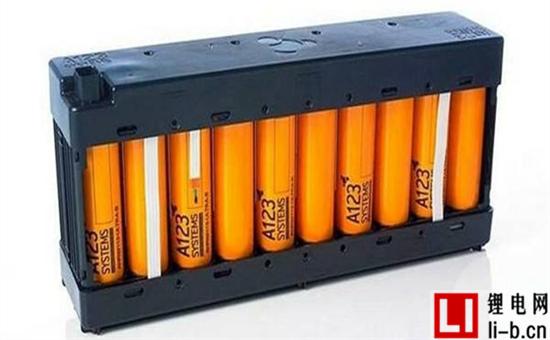

Cylindrical batteries have taken the lead in mass production of high-nickel products, and square and soft-pack batteries have broken through. Judging from the technological progress of mainstream enterprises, Japan and South Korea are leading the mass production of high-nickel power batteries, and domestic enterprises are catching up quickly. Cylindrical battery faucet company BAK's high-nickel products have been mass-produced, and will be used in the Jianghuai iEV7S, the first model of Jianghuai Volkswagen, and the new qi3 and Xiaopeng models of the new car.

The high-nickel products of the square and soft-package leading companies in Ningde and Fueng are expected to be measured in the four seasons. In 2019, the industry will usher in a universal breakthrough in mass production of high-nickel products.

In 2020, the demand for NCM811 will reach 77,000 tons, and the market size will break 20 billion. Due to the low production difficulty of NCM111 and 523, it will be the mainstream in 2017. In 2018, it will transition to single crystal 523 and 622 systems. 811 will start to increase its volume. In 2019, the proportion of 811 will increase significantly. In 2020, the demand for NCM811 will reach 77,000 tons. The market size will reach 20.5 billion.

At present, among the four main materials of lithium batteries , the market concentration of ternary positive electrode is the lowest. In 2017, Rongbai, which has the highest shipment of ternary positive electrode, has a market share of less than 13%, and accounts for the market share of negative electrode, separator and electrolyte. The rate is generally 25-30%, the ternary positive electrode market pattern is the most dispersed, and the concentration of lithium cobaltate is also significantly lower than the same positive electrode. The reason why the high-nickel positive electrode will reshape the industrial structure is that the technical threshold is greatly improved, and the high-quality nickel anode is very difficult. The parameter control of the specific doping coating and the process control of the production line are much more difficult. The difference between 333 and 523 is not big, and the difficulty of 523 to 622 is slightly improved, but 811 is a sudden change point, and the difficulty is significantly improved. The number of manufacturers who can truly achieve high-nickel positive bulk shipments will be significantly reduced.

At the beginning of the high-nickel cathode industrialization, many manufacturers actively promote the high nickel cathode production capacity. From the perspective of absolute capacity planning, high-nickel cathode capacity will be intensively launched in 2018-2019, and high-nickel cathode capacity will reach 170,000 by the end of 2019. Tons or so. However, there is still a long way to go to produce high-quality products in batches. In particular, some manufacturers have more experience in NCA production than NCM811, and customer certification also requires a longer period. In the positive cost structure, the cost of raw materials accounts for about 80%, and price competition will not be the main means. It is expected that the competition will be more orderly.

Compared with NCM523, NCM811 decreased the cobalt content from 12.21% to 6.06%. The amount of cobalt used in the power battery decreased from 0.22kg to 0.09kg per kwh. The subsequent increase in the proportion of nickel will further decrease. Under the condition of cobalt price of 550,000/ton, the cost of single-ton 811 cathode can be reduced by about 34,000 compared with 523, and the higher the cobalt price, the more obvious the cost advantage. The processing cost of 811 anode is about 20,000/ton higher than 523, and it is expected to be reduced to 10,000/ton in the future. Therefore, the current total cost of 811 is about 14,000/ton lower than 523.

At present, the price of NCM811 is about 240,000 yuan / ton, while the mainstream price of NCM523 power is 21-21.5 million yuan / ton, the price difference is 2.5-3 million / ton. Considering that the total cost of NCM811 positive electrode is about 14,000/ton lower than 523, the gross profit per ton is increased by 3.9-4.4 million, and the profitability is significantly improved. Gross profit margin will gradually decline, and steady-state profitability will also be higher than 523.

The technical content of ternary 523 and 111 cathodes is more in the precursor phase, while in the high-nickel cathode system, the technical content of the cathode sintering section is also significantly increased. In the mode of processing fee pricing, the steady state is high nickel anode link. The gross profit will also be higher than the 523 products. At present, the gross profit margin of Sanyuan 523 is 15%, 622 is 20%, and 811 is about 25%. Considering that with the high nickel cathode capacity, 811 gross margin is expected to fall to a relatively stable 20%.

Hardcore technology dry goods:

Among the ternary materials , the three elements work differently, and the relative content affects the overall material properties:

1) Ni is one of the main active substances, which has a significant effect on the capacity, and its relative content is increased, and the gram capacity is increased;

2) Co is also an active substance, which can stabilize the layered structure of the material, reduce the cation mixing, and facilitate the deep discharge of the material, thereby increasing the discharge capacity of the material;

3) Mn4+ is electrochemically inert and mainly functions as a stable structure.

Ni exhibits high capacity and low safety; Co exhibits high cost and high stability; Mn exhibits high safety and low cost. In order to obtain a low-cost, high-capacity ternary material, by increasing the relative content of Ni and decreasing the ratio of Co and Mn, the discharge capacity is significantly increased, but the cycle performance and thermal stability are almost linearly decreased.

The reasons for the poor cycle performance and thermal stability of high nickel cathodes are mainly due to:

1) Li/Ni is prone to mixing and the high nickel positive electrode is more serious. Due to the close proximity of Ni2+ and Li+, Li+ deintercalation forms vacancies during delithiation, and Ni2+ easily migrates to the lithium level, causing lithium to precipitate. During the repeated reaction, the mixing ratio increases and the material hierarchy collapses. This results in a significant performance degradation and therefore poor cycle performance.

2) The increase of Ni content in the ternary material reduces the thermal decomposition temperature, increases the heat release, and deteriorates the thermal stability of the material. In addition, the high nickel positive electrode Ni4+ content is high, Ni4+ has strong oxidizing property, which will decompose the electrolyte. In order to maintain the charge balance, oxygen will be released from the material, and the crystal structure will be destroyed, thereby deteriorating the stability of the material.

Therefore, the high nickel positive electrode needs to be doped and coated to modify the material to be applied in practical industrialization.

1) bulk phase doping modification: improve the structural stability of the material by changing the lattice constant of the material or the valence state of some elements in the material, improve the electronic conductivity and ionic conductivity of the material, and reduce the cation mixing. The doping is mainly divided into cationic doping (Al, Mg, Ti, Zr, Mo, Cr), anionic doping (F), and anion-cation co-doping (AlF3, MgF2). Doping of cationic Al, Mg, etc. can suppress Li/Ni mixing, suppress phase transition in charge and discharge process, and improve cycle performance. Anionic F doping can replace some M-O bonds in the structure into more stable M-F bonds, improve structural stability, reduce the reaction between the positive electrode and the electrolyte, reduce the increase of interface resistance during the cycle, and improve cycle stability.

2) Surface coating modification: reduce the oxidative decomposition of the electrolyte caused by direct contact between the positive electrode and the electrolyte, reduce the collapse of the crystal structure during the charge-discharge cycle, and inhibit the growth of the SEI film, thereby improving the cycle of the battery. And safety performance. The coating material is mainly an inorganic material without electrochemical activity, such as AlPO4, Al2O3, AlF3, MgO, TiO2 and the like. At the same time, the excessive surface alkalinity affects the electrochemical performance of the positive electrode material , and affects the coating quality of the material. The surface coating can effectively reduce the surface alkalinity of the ternary material.

The core technology of the high nickel positive electrode is the doping and coating process, and the precision and process requirements of the sintering equipment are also greatly improved, and the technical difficulty is significantly increased.

At present, the mainstream production process adopted in the industrial production of ternary positive electrode is: coprecipitation method for preparing precursor, and then solid-phase sintering with lithium source to form ternary material. The doping is in both the precursor and the sintering step, and the coating is mainly concentrated in the sintering process. The main reason is that the precursor liquid phase coating process is technically difficult, and the fine chemical control is required. Multiple sintering.

Difficulties in doping cladding are doping cladding element selection, process methods, and parameter control to achieve a uniform doping coating effect. The core equipment kiln of the sintering process is divided into multiple temperature zones. The temperature control accuracy of the high-nickel positive electrode in the multi-temperature zone during sintering is significantly higher than that of the 523 and other products. At the same time, the Ni/Li mixing is induced by the presence of oxygen vacancies in the positive electrode material. The high-nickel cathode material needs to be sintered in a pure oxygen atmosphere, which requires extremely high precision and tightness of the equipment. The high-nickel positive electrode needs to be sintered once, and unlike the 523 and other products, the overall process requirements are also significantly improved, and the technical difficulty is significantly increased.

在线地图

在线地图 收藏本站

收藏本站