NEWS |

News Details

Position:

Home>

News Details

Technical Interpretation: Influence of Rolling Temperature of Pole Pieces on Lithium Batteries

Category: Industry Information

Date: 2018-06-08

Click: 3676

Collection:

Original Link: displaynews.html?id=3313876139852608

Lithium Grid News: The pole piece manufacturing process is mainly the coating and rolling process, in which the rolling process is critical.

The compaction density of the surface coating material has a very important relationship with the electrochemical performance of the battery . Reasonable compaction density can effectively increase the electrochemical performance of the battery, reduce the contact resistance and AC impedance of the electrode, and increase the participation in the electrochemical reaction. The active material area, thereby significantly improving the electrochemical performance of the pole piece coating material. The manufacture of lithium-ion battery pole pieces belongs to the high-precision manufacturing category. The pole piece rolling is different from the strip and strip rolling. The strip and strip rolling is a process in which the metal material is longitudinally extended and laterally widened. The material density during the rolling process is not A change has occurred. The electrode material on the surface of the battery pole piece is a pore structure. During the rolling process, the electrode material on the positive and negative electrode sheets is compacted and the density changes. The pole piece rolling is a process in which the pore structure is filled and the coating particles are gradually compacted. The purpose of the pole piece rolling is as follows:

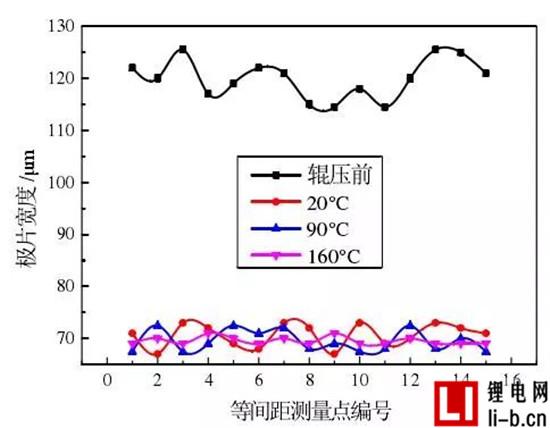

Figure 1 Pole thickness at different rolling temperatures Figure 1 is a thickness curve of a pole piece coated with a thickness of 100 μm at different rolling temperatures, as shown in the figure, as the rolling temperature increases from 20 ° C to 90 ° C and then increases to 160 ° C, the pole piece The thickness deviation is reduced from ±1.9μm to ±1.3μm and then to ±0.8μm, and the thickness uniformity of the pole piece is gradually increased. This is because the deformation resistance of the pole piece coating decreases and the plasticity becomes better as the rolling temperature increases. Make the surface thickness of the pole piece more uniform.

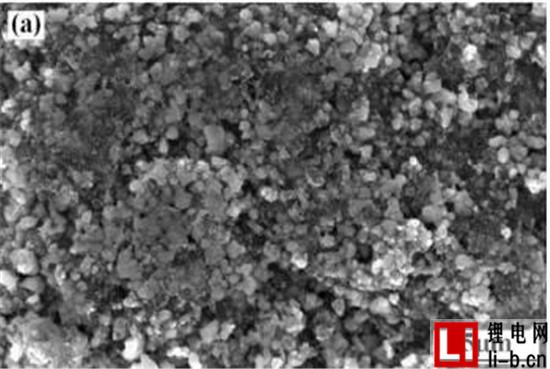

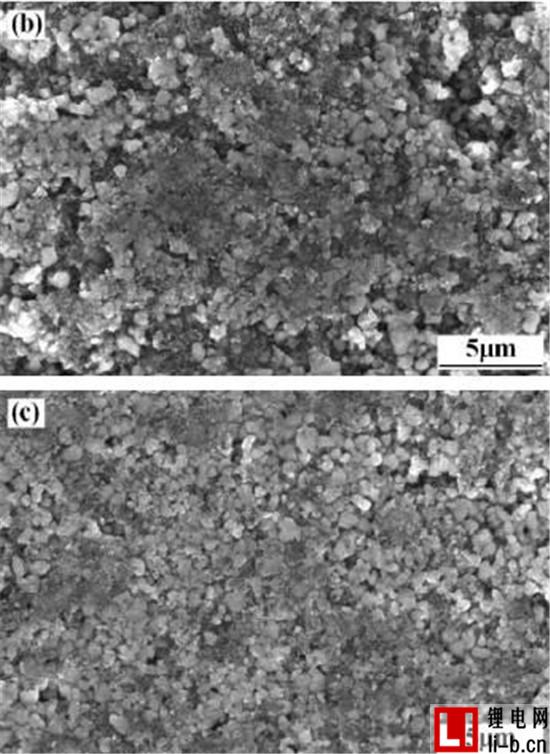

Figure 2 SEM image of the surface of the pole piece coating material at different rolling temperatures Figure 2 is the SEM image of the surface of the pole piece coating material at different rolling temperatures. As shown in the figure, when the rolling temperature is 20 °C, the surface of the pole piece coating has a relatively tight particle combination, and some areas are not tight enough. There is a small amount of micropores; when the rolling temperature is 90 °C, the surface of the pole piece coating is tightly bonded, the tight bonding area is increased, and the number of micropores is decreasing; when the rolling temperature is 160 ° C, the pole piece is coated. The degree of tight binding of the surface particles is further increased, the tightly bound region is further increased, and the number of micropores is further reduced. The difference in rolling temperature changes the deformation resistance of the coating, so that the surface of the pole piece coating material has different densities.

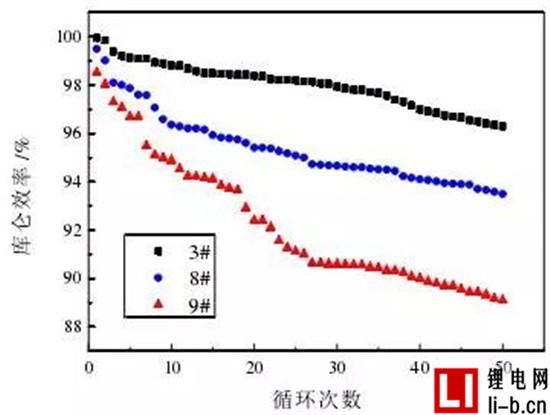

Figure 3 Coulombic efficiency of each sample cell Fig. 3 shows the coulombic efficiency of each sample battery, and 9#, 8#, and 3# are batteries produced by rolling the pole pieces at 20 ° C, 90 ° C, and 160 ° C, respectively. As can be seen from Figure 3, the coulombic efficiency of the sample is also increased when the rolling temperature is increased from 20 ° C to 90 ° C and then increased to 160 ° C. The coulombic efficiency is the ratio of the specific discharge capacity to the charge specific capacity in the same charge and discharge cycle. When the thickness uniformity of the pole piece is increased, the resistance is lowered and the coulombic efficiency is correspondingly increased.

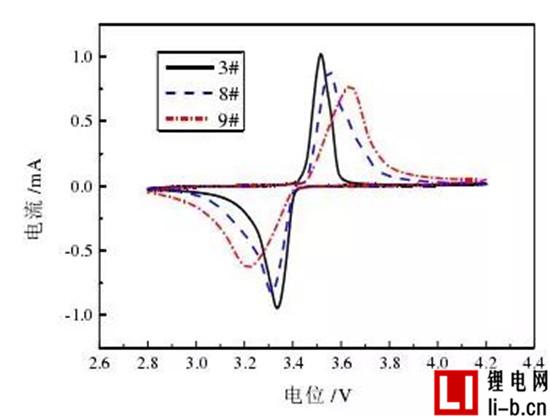

Figure 4 Cyclic volt-ampere performance of each sample cell Fig. 4 is a cyclic voltammetry performance curve of each sample, and 9#, 8#, and 3# are batteries produced by rolling the pole pieces at 20 ° C, 90 ° C, and 160 ° C, respectively. It can be seen from the figure that when the rolling temperature is 160 °C, the upward oxidation peak and the downward reduction peak have better symmetry, the peak position difference is also the smallest, and the reversibility of charge and discharge is also the best, which proves the coulombic efficiency. It must be high. source: [1] Liu Binbin. Theoretical and experimental research on precision manufacturing of power lithium-ion battery pole pieces [D]. Taiyuan University of Science and Technology, 2017. |

Online map

Online map Collection Website

Collection Website